A consultancy project is a typical starting point for many of our customers. If you have a problem involving particles and are not sure if or how Aspherix® can help, this is the way to go. With our experience we can provide answers to your questions and introduce you to our software. We always like to stretch the borders of what is possible to simulate and love a good challenge.

Our team is composed of Senior Engineers and Scientists from Mechnical & Electrical Engineering, Physics, Mathematics and Computer Science and has conducted more hundreds of projects for blue chip companies in all industries.

We are the core developers of ASPHERIX® and CFDEM®coupling. We know how to transform science and engineering expertise into CAE software. We constantly improve the models within our simulation software which is designed to be highly customizable to reflect the variety of challenges we see in our consultancy projects.

We are used to working in a swift and agile way. The Open Source license of our software in combination with our expertise allows us to provide you an unprecedented time to market.

We picked a few of our consulting cases to demonstrate how our software can support different applications

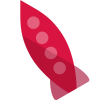

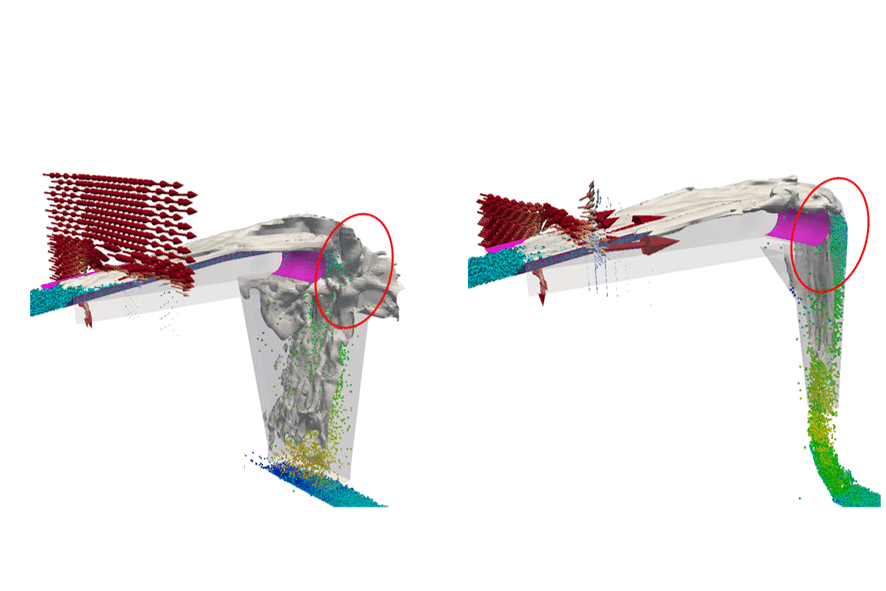

The goal of this case study with Aspherix and CFDEMcoupling was the optimization of a mower deck with respect to ths cut quality. Since the design contains blades with intersection trajectories it was not possible to use sliding meshes. A new IB approach designed for mower deck applications was used.

This application case combines numerous functionalities. Particles are wetted by a spray and heated by convection. The heating of the particles causes them to dry while powder leads to a coating of the particles. At collision, the coating of the particles undergoes attrition and the attrition is dispersed in the gas as dust.

CFD-DEM simulations can help to improve blast furnace operational parameters such as the impact of charging recipe on the uniformity of solid fraction, the impact of hot blast mass-flow rate and velocity on race way size and shape.

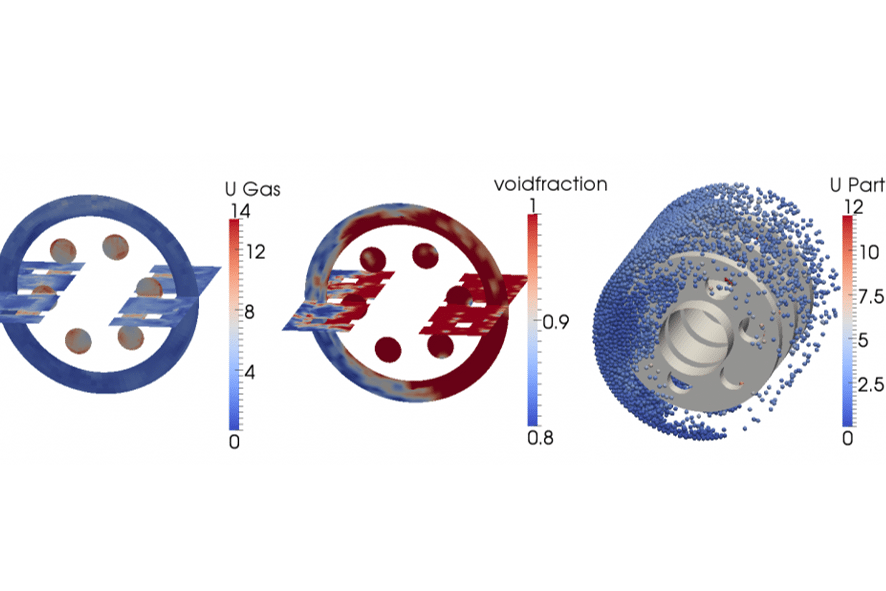

Ball mills are widely used in the minerals and mining industry. CFD-DEM simulations can help to improve their performance and reduce down-time and maintenance.

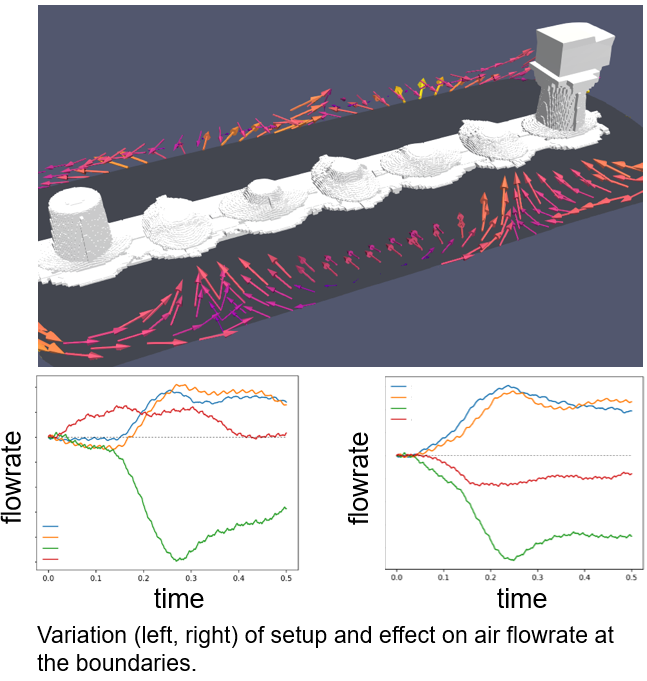

The simulation above shows the dust emission in a transfer chute system, in both a simple and an improved geometry. While in the simple geometry, dust can escape the transfer chute and can pose a possible health and explosion hazard, the dust is kept within the transfer chute in the improved geometry.

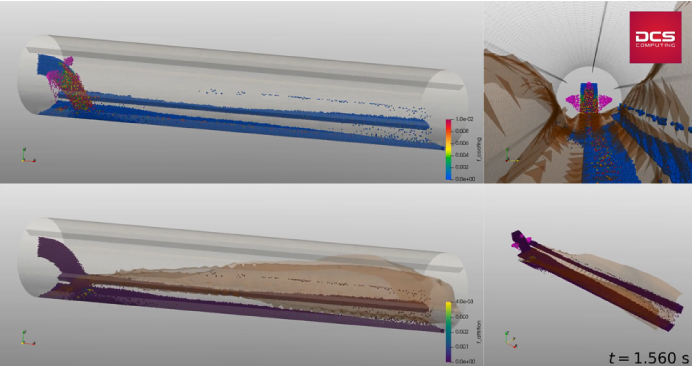

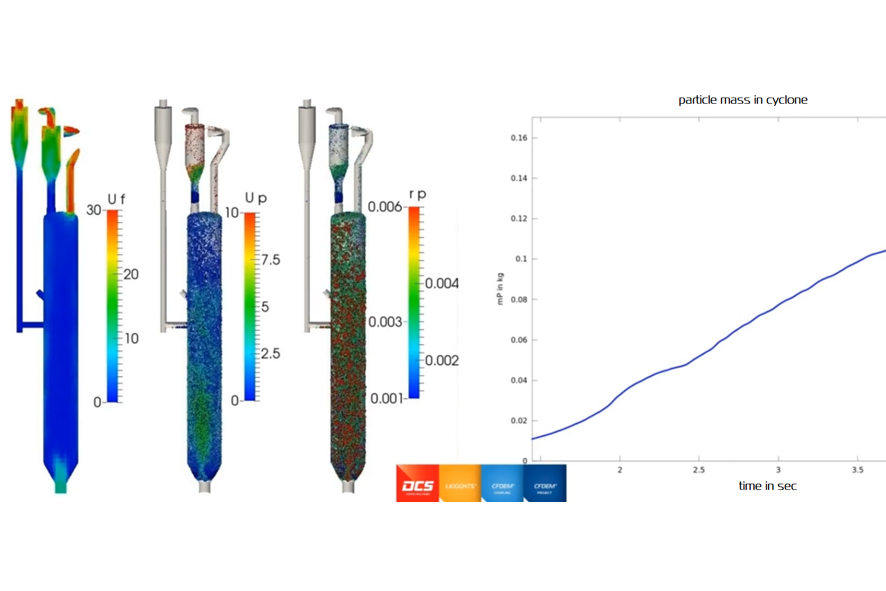

Circulating fluidized beds are widely used in chemical, process and metallurgical industry. The simulation of a fluidized bed can help to improve heat and mass transfer reaction rate, optimize residence time and product uniformity.